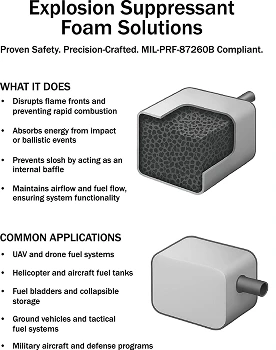

Explosion Suppressant Foam Solutions

Proven Safety. Precision-Crafted. MIL-PRF-87260B Compliant.

At Pacific West Foam, we specialize in manufacturing reticulated open-cell polyurethane foam systems designed to minimize the risk of fuel tank explosions. Our explosion suppressant foams are trusted in military, aerospace, and industrial applications to enhance safety, manage fuel stability, and prevent catastrophic failures due to detonation or impact.

Available Foam Grades

MIL-PRF-87260B GRADE 1 – 15 PPI

MIL-PRF-87260B GRADE 2 – 30 PPI

MIL-DTL-83054C TYPE 2 – Yellow

MIL-DTL-83054C TYPE 4 – Dark Blue

MIL-DTL-83054C TYPE 5 – Light Blue

Ethafoam® Polyethylene

Organizations We’ve Proudly Served

1. Defense & Military

2. Aerospace

3. Industrial & Commercial

Why Our Foam Works Where It Matters

At Pacific West Foam Industry, Inc., we understand that fuel safety and system stability are non-negotiable in high-performance environments. That’s why our fuel-stabilizing foam is engineered to deliver consistent, passive protection without adding complexity. Whether it’s used in an aircraft, military vehicle, or performance machine, our foam provides reliability where it counts.

Benefits:

Our reticulated polyurethane foam offers a range of advantages designed to improve safety, durability, and performance:

Slosh Control – Helps minimize the violent movement of fuel during turns, takeoffs, landings, or sudden stops.

Vibration Damping – Absorbs shock and reduces stress on tanks and surrounding components.

Lightweight Design – Keeps overall system weight low without sacrificing structure or function.

No Electronics Needed – Functions passively with no moving parts or maintenance-intensive systems.

Fuel-Compatible – Works effectively with gasoline, diesel, and aviation fuels.

Reliable in Any Fill State – Performs whether tanks are full, half-full, or near empty.

Debris Protection – Acts as a buffer against internal foreign object damage.

Common Applications:

Pacific West Foam explosion suppressant materials are commonly used in:

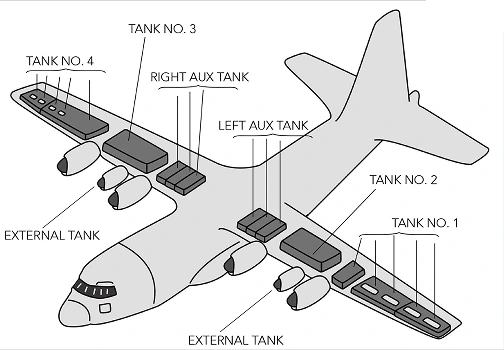

- UAV and drone fuel systems

- Helicopter and aircraft fuel tanks

- Fuel bladders and collapsible storage

- Ground vehicles and tactical fuel systems

- Military aircraft and defense programs

Our foam is widely compatible with both aviation fuels (JP-8, Jet-A) and automotive fuels (gasoline, diesel). It’s also tailored for custom geometries, making it ideal for retrofits or complex internal tank designs

What It Does

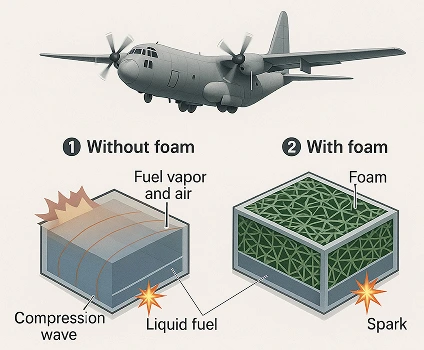

Our lightweight polyurethane foam is installed inside fuel tanks to reduce the likelihood of explosion by:

- ✔ Disrupting flame fronts and preventing rapid combustion

- ✔ Absorbing energy from impact or ballistic events

- ✔ Preventing slosh by acting as an internal baffle

- ✔ Maintaining airflow and fuel flow, ensuring system functionality

The foam’s open-cell structure allows it to fill the internal volume of tanks without impeding fuel delivery or venting. It is particularly valuable in environments where high maneuverability, rapid acceleration, or combat risk increases the likelihood of fuel volatility.

Why Choose Pacific West Foam?

- ✔ MIL-PRF-87260B compliant: Our foam meets military standards for explosion suppression.

- ✔ Cut-to-fit precision: Each unit is engineered and cut to match your exact tank dimensions.

- ✔ Long-term durability: Designed to retain structure and performance over extended use.

- ✔ Engineering support: Every project is reviewed by experienced professionals to ensure compatibility and success.

Protect What Matters

Explosion suppression is not just about compliance—it’s about saving lives and protecting mission-critical equipment. Pacific West Foam provides foam systems that help absorb and disperse energy, protect fuel containment, and reduce the chance of ignition in even the harshest conditions.

Contact us today to learn more, request a quote, or speak with one of our foam specialists about your project.